SNOA975B March 2018 – February 2023 INA333 , INA818 , INA819 , INA823 , INA826 , INA828 , OPA187 , OPA189 , OPA196 , OPA2189 , OPA325 , OPA388 , OPA391 , OPA4189 , PGA309 , XTR111 , XTR115 , XTR116 , XTR300

1 Application Brief

Introduction

Pressure transmitters are used to monitor weight, level, force and flow in industrial process control systems. The primary challenges encountered when designing pressure transmitters are nonlinearities and temperature dependence. Overcoming these challenges requires the proper implementation of an appropriate operational amplifier (op amp) and a deep understanding of, the precision, voltage range, and drive characteristics of the op amp.

Pressure Sensors

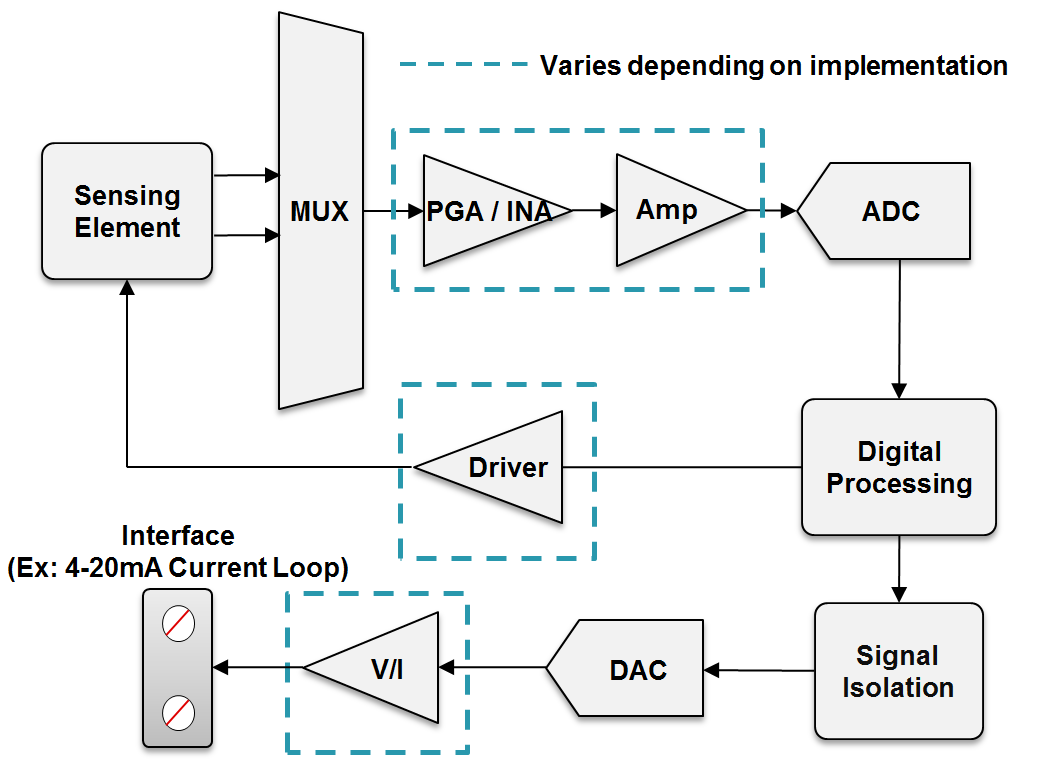

The four most common types of pressure sensors used in pressure transmitter applications are: Resistive, Capacitive, Silicon, and Linear Variable Differential Transformer (LVDT) with resistive strain gauges being the most commonplace. These four variants all use similar paths in the pressure transmitter signal chain. #X1799 illustrates a block diagram of a typical pressure transmitter signal path.

Figure 1-1 Common

Pressure Transmitter

Figure 1-1 Common

Pressure Transmitter Block Diagram

Various sensors and interfaces call for diverse device implementations.

- Instrumentation amplifiers, also known as INAs, are used to amplify small differential signals in the presence of larger or noisy common-mode signals

- Programmable-gain amplifiers, also known as PGAs, can provide higher gain accuracy using selectable gain steps

- Capacitive, LVDT and silicon sensors require implementation of a driver amplifier, which provides the excitation required for the sensor to capture changes in pressure or displacement.

- Voltage-to-current (V/I) converters are used to interface with commonly used 4–20-mA current loops.

Instrumentation Amplifiers

The output signal from the sensing element requires amplification prior to digital conversion as sensor signals are typically very small and can commonly be in the low single millivolt range. Instrumentation amplifiers provide the necessary amplification of differential signals while providing low noise and good rejection of the common-mode signals.

The INA819 instrumentation amplifier with super-beta input transistors provides exceptionally low input offset, offset drift, noise, and input bias current to help maintain signal accuracy when interfacing sensing elements. In addition, the wide supply (4.5 V to 36 V) and input overvoltage protection up to 60 V beyond the supplies enables a wide variety of sensing elements.

Programmable Gain Amplifiers

Sensing elements typically output a nonlinear signal over temperature and pressure changes. A programmable gain amplifier with linearization circuitry, such as the PGA309, can be used to adjust for nonlinearities. The PGA309 is a programmable analog signal conditioner designed specifically for bridge sensors. The output of the PGA309 is sufficient to drive any 5-V analog-to-digital converter (ADC). Any higher-voltage ADC must be buffered by a low-noise, low-offset voltage and low-drift op amp to extend the output signal and make use the full dynamic range of the ADC. The OPA189 is a good option for a buffer amplifier, given the wide voltage range up to 36 V, zero-drift, and low-noise (5.8 nV/√Hz) performance.

Driver Amplifiers

Capacitive-, LVDT- and Silicon-based sensing elements require excitation by an op amp with sufficient drive characteristics necessary to enable the sensing element to capture minute changes in pressure and displacement. The important design parameters for these op amps are output current and capacitive load drive. The OPA196 op amp offers sufficient output current (65 mA) and high capacitive load drive (1 nF) capability making the device a good choice for this application.

| INA/PGA | Key Benefits |

|---|---|

| INA819 | Wide supply (4.5 V to 36 V), high precision (35 μV, 0.4 μV/°C), low noise (8 nV/√Hz) instrumentation amplifier with input overvoltage protection |

| INA823 | Low power (180 µA), wide supply (2.7 V to 36 V), precision (100 µV), instrumentation amplifier with input overvoltage protection and below ground input range. |

| INA333 | Ultra-low power (50 μA), high precision (25 μV, 0.1 μV/°C), zero-drift instrumentation amplifier |

| PGA309 | Programmable gain amplifier offering design versatility while mitigating pressure and temperature nonlinearities through highly integrated linearization circuit, fault monitoring and digital temperature compensation. |

| ADC Buffer | Key Benefits |

|---|---|

| OPA2182 | Industry leading precision (0.012 μV/°C, 4 μV max), low-noise (5.7 nV/√Hz), zero-drift op amp with MUX-friendly inputs |

| OPA210 | Ultra-low noise (2.2 nV/√Hz), wide-bandwidth (14 MHz), high-precision, super-beta op amp |

| THP210 | High-precision (40 μV, 0.1μV/°C), high-voltage (36 V), low-noise (3.7 nV/√Hz), fully-differential amp and ADC driver |

| Driver Amplifier | Key Benefits |

|---|---|

| OPA202 | Low noise (0.2 µVPP, 9 nV/√Hz), heavy capacitive drive (25 nF), super-beta, precision op amp |

| OPA196 | High-capacitive load drive (1 nF) and high-output current (65 mA) enables capacitive sensor excitation. |

Device Selection

| Voltage-to-Current (Integrated) | Key Benefits |

|---|---|

| XTR115 XTR116 |

Integrated solutions for 4–20-mA loops provide low nonlinearity error and the convenience of an on-chip 5-V voltage regulator and a precision VREF. |

| XTR111 | Cost-effective 4–20-mA driver provides an integrated device with low nonlinearity, good accuracy, wide supply and output error flag. |

| XTR300XTR305 | Integrated 4–20-mA loop solution: output can be configured as current or voltage without external shunt resistor and provides error flags and monitor pins for fault detection (XTR305 is a cost effective version) |

Device Selection

| Voltage-to-Current (Op Amps) | Key Benefits |

|---|---|

| OPA187 | Low-power and zero-drift architecture reduces power consumption and provides high precision over the full industrial temperature range. |

| OPA391 | Micro-power (24 µA), high-precision, wide bandwidth, RRIO op amp with e-Trim™ |

Voltage-to-Current Converters

A common interface in pressure transmitter applications is the 4–20-mA current loop, which uses a precision, low-power op amp to create a measurable current range from a voltage range. The requisites of the op amp in this application are low power and high precision. The OPA391, an e-Trim™ op amp, features 45-µV maximum offset and 24 µA of quiescent current, making the device a good candidate for such requirements.

An integrated solution can also be implemented using an XTR115, XTR300, or XTR305, which are precision current output converters designed to provide signal conditioning of low level signals and translation of them to a robust, noise-immune 4–20-mA transmission.

Temperature, Power, and Nonlinearities

In a real application environment, changes in temperature can affect the behavior of key device specifications, such as input offset voltage and input bias current. This impact can be mitigated by selecting zero-drift op amps.

For applications with power constraints such as battery powered sensors or 4–20-mA loops with many sensor nodes, low-power devices that maintain high precision are available.

Nonlinearities in sensor output over pressure or temperature can be corrected by adjusting the excitation of the sensor. This function can be implemented through digital processing or integrated linearization circuitry.

Summary

The implementation of amplifiers in pressure transmitters varies depending on sensing elements and interfaces. Issues with wide temperature drifts and nonlinearities can be mitigated through the proper use of instrumentation amplifiers, programmable gain amplifiers and op amps. Table 1-6 outlines some devices that are commonly used in pressure and field transmitter applications.

| Media | Title |

|---|---|

| Technical Guide | TI Field Transmitter Solutions Guide |

| Application Brief | Offset Correction Methods: Laser Trim, e-Trim™, and Chopper |

| Application Report | Selecting an A/D Converter |

| Application Brief | Zero-Drift Amplifiers: Features and Benefits |

Application Brief |

Super-beta Input Amplifiers: Features and Benefits |